Fluid coupling and its UN known information

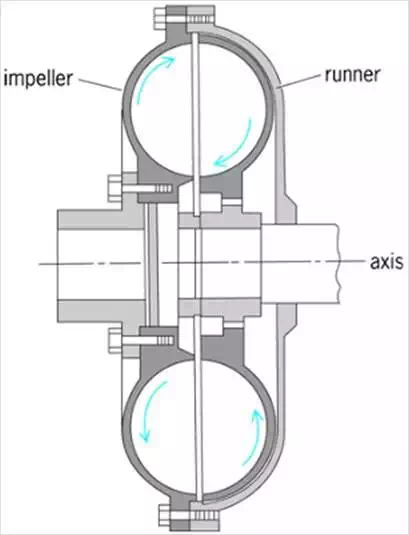

It is a device for transmitting rotation between shafts by means of the acceleration and deceleration of a hydraulic fluid (such as oil). Also known as hydraulic coupling. Structurally, a fluid coupling consists of an impeller on the input or driving shaft and a runner on the output or driven shaft. The two contain the fluid. Impeller and runner are bladed rotors, the impeller acting as a pump and the runner reacting as a turbine. Basically, the impeller accelerates the fluid from near its axis, at which the tangential component of absolute velocity is low, to near its periphery, at which the tangential component of absolute velocity is high. This increase in velocity represents an increase in kinetic energy. The fluid mass emerges at high velocity from the impeller, impinges on the runner blades, gives up its energy, and leaves the runner at low velocity.

Hydraulic fluid couplings transfer rotational force from a transmitting axis to a receiving axis. The coupling consists of two toroids — doughnut-shaped objects — in a sealed container of hydraulic fluid. One toroid is attached to the driving shaft and spins with the rotational force. The spinning toroid moves the hydraulic fluid around the receiving toroid. The movement of the fluid turns the receiving toroid and thus turns the connected shaft.

Although fluid couplings use hydraulic fluid within their construction, the mechanism loses a portion of its force to friction and results in the creation of heat. No fluid coupling can run at 100 percent efficiency. Excessive heat production from poorly maintained couplings can result in damage to the coupling and surrounding systems.

A fluid coupling is a hydrodynamic device used to transmit rotating mechanical power. It has been used in automobile transmissions as an alternative to a mechanical clutch. It also has widespread application in marine and industrial machine drives, where variable speed operation and/or controlled start-up without shock loading of the power transmission system is essential.