By moses dhilip kumar

abstract

The

hydrogen gas injector plug for generating hydrogen gas from ambient air drawn

into the piston chamber of an engine includes an array of nozzles fabricated

from a metal or a mixture of metals. When heated to a pre-determined

temperature, the metallic nozzles react with atmospheric water to disassociate

hydrogen gas. The hydrogen gas is injected from the nozzles into the piston

chamber and mixed with air. An ignition device ignites the mixture of hydrogen

and air so that it burns to power the piston in a conventional manner. The

metallic nozzle is heated via a copper conductor connected to a source of

electric current.

NEED FOR ALTERNATIVE FUELS

The

rising cost and diminishing supply of hydrocarbon fuels, i.e. gasoline, have

increased the criticality of developing or finding alternative fuels.

Furthermore, pollution caused by burning hydrocarbon fuels is suspected of

creating a “greenhouse” effect in the atmosphere, thereby creating problems

that may have a bearing on the future course of human civilization. The world

would certainly welcome a device that could utilize a virtually inexhaustible

supply of a common element to power internal combustion engines, which device

would also cause production of pollution-free byproducts. Some well known

alternative fuels include biodiesel, bio-alcohol (methanol, ethanol, butanol),

chemically stored electricity (batteries and fuel cells), hydrogen, non-fossil

methane, non-fossil natural gas, vegetable oil and other biomass sources.

HYDROGEN GAS AS AN ALTERNATE FUEL

Hydrogen

is one of two natural elements that combine to make water. Hydrogen is not an

energy source, but an energy carrier because it takes a great deal of energy to

extract it from water. It is useful as a compact energy source in fuel cells.

Many companies are working hard to develop technologies that can efficiently

exploit the potential of hydrogen energy. The use of hydrogen as a fuel to

power engines has been contemplated for many years. Combustion of this hydrogen

produces only pollution-free water. Unfortunately, hydrogen poses many risks

when stored in large quantities, thus creating many problems in making the gas

available to the general public. Thus a hydrogen gas injector plug solving the

aforementioned problem is desired.

Hydrogen does not come as a

pre-existing source of energy like fossil fuels, but is first produced and then

stored as a carrier, much like a battery. Hydrogen for vehicle uses needs to be

produced using either renewable or non-renewable energy sources. A suggested

benefit of large-scale deployment of hydrogen vehicles is that it could lead to

decreased emissions of greenhouse gases and ozone precursors.

A hydrogen vehicle uses hydrogen as

its onboard fuel for motive power. The term may refer to a personal

transportation vehicle, such as an automobile, or any other vehicle that

uses hydrogen in a similar fashion, such as an aircraft. There are basically

two conventional methods of powering a engine using hydrogen, they are:

·

In hydrogen internal

combustion engine vehicles, the hydrogen is combusted in engines

in fundamentally the same method as traditional internal combustion engine vehicles.

- In

fuel-cell conversion, the hydrogen is reacted with oxygen to produce water

and electricity, the latter being used to power an electric traction

motor.

•

Wide range of flammability

•

Low ignition energy

•

Small quenching distance

•

High auto-ignition temperature

•

High flame speed at stoichiometric ratio

•

High diffusivity

•

Very low density

But...

The

challenges in using the hydrogen in vehicles are production, storage, transport

and distribution. Each of these requires great amounts of energy and safety

precautions. Because of all these challenges the efficiency of hydrogen will

not exceed 25%.

HYDROGEN

PRODUCTION

The

molecular hydrogen needed as an on-board fuel for hydrogen vehicles can be

obtained through many thermo-chemical methods utilizing natural gas, coal (by a

process known as coal gasification), liquefied petroleum gas, biomass (biomass

gasification), by a process called thermolysis, or as a microbial waste product

called bio-hydrogen or Biological hydrogen production. Most of today's hydrogen

is produced using fossil energy resources and 85% of hydrogen produced is used

to remove sulfur from gasoline. Hydrogen can also be produced from water by

electrolysis or by chemical reduction using chemical hydrides or aluminum.

Current technologies for manufacturing hydrogen use energy in various forms,

totaling between 25 and 50 percent of the higher heating value of the hydrogen

fuel, used to produce, compress or liquefy, and transmit the hydrogen by

pipeline or truck. Electrolysis is currently the most inefficient method of

producing hydrogen, uses 65 to 112 percent of the higher heating value on a

well-to-tank basis

In

addition to the inherent losses of energy in the conversion of feed stock to

produce hydrogen, which makes hydrogen less advantageous as an energy carrier,

there are economic and energy penalties associated with packaging,

distribution, storage and transfer of hydrogen.

DIFFICULTIES

IN STORING HYDROGEN GAS

Hydrogen

for use as fuel must first be produced using another energy source, making it a

means to transport energy, rather than an energy source, similar to a

rechargeable battery. One existing method of hydrogen production is steam

methane reformation; however, this method requires methane (most commonly

available as natural gas), which raises sustainability concerns. Another method

of hydrogen production is through electrolysis of water, in which electricity

generated

from any

source can be used. Photo electrolysis, bio-hydrogen, and biomass or coal

gasification have also been proposed as means to produce hydrogen.

Hydrogen

is currently impractical as an alternative to fossil-based liquid fuels. While

hydrogen has a very high energy content by weight, it has very low energy

content by volume, making it very challenging to store in average-sized

vehicles. Hydrogen can be stored as compressed hydrogen, as cryogenic liquid

hydrogen, or in compounds containing hydrogen which must undergo a chemical

change to release the gas such as metal hydrides. However, because of the lower

volumetric energy, hydrogen gas tanks would need to be two to three times as

large for compressed hydrogen storage as conventional gasoline tanks.

Although hydrogen fuel

cells generate no CO2, production of the hydrogen for cars currently

creates higher emissions than gasoline cars. While methods of hydrogen

production that do not use fossil fuel would be more sustainable, currently

renewable energy represents only a small percentage of energy generated, and

power produced from renewable sources can be used in electric vehicles and for

non-vehicle applications.

Hydrogen

has a very low volumetric energy density at ambient conditions, equal to about

one-third that of methane. Even when the fuel is stored as liquid hydrogen in a

cryogenic tank or in a compressed hydrogen storage tank, the volumetric energy

density (mega joules per liter) is small relative to that of gasoline. Hydrogen

has a three times higher energy density by mass compared to gasoline (143 MJ/kg

versus 46.9 MJ/kg). Because of the energy required to compress or liquefy the

hydrogen gas, the supply chain for hydrogen has lower well-to-wheel efficiency

but a higher tank-to-wheel compared to gasoline IC's. Some research has been

done into using special crystalline materials to store hydrogen at greater

densities and at lower pressures. A recent study by Dutch researcher Robin Gremaud

has shown that metal hydride hydrogen tanks are actually 40 to 60-percent

lighter than an equivalent energy battery pack on an electric vehicle

permitting greater range for hydrogen cars.

DISADVANTAGES

• Fuelling

fuel cells is still a problem since the production, transportation,

distribution and storage of hydrogen is difficult.

•

Reforming hydrocarbons via reformer to produce hydrogen is technically

challenging and not clearly environmentally friendly.

• The

refueling and the starting time of fuel cell vehicles are longer and the

driving range is shorter than in a “normal” car.

• Fuel

cells are in general slightly bigger than comparable batteries or engines.

• Fuel

cells are currently expensive to produce, since most units are hand-made.

• Some

fuel cells use expensive materials.

• The

technology is not yet fully developed and few products are available.

CONSTRUCTION OF HYDROGEN INJECTOR PLUG

The

hydrogen gas injector plug is used for generating hydrogen gas from ambient air

drawn into the piston chamber of an engine. The plug comprises an array of

nozzles fabricated from one or a mixture of metals. When heated to a

pre-determined temperature, the metallic nozzles become “white-hot” and

generate

photons

that react with atmospheric water to disassociate hydrogen gas there from. The

nozzle is designed so that no reaction will occur if the temperature is below

350° F. The hydrogen gas is injected from the nozzles into the piston chamber

and mixed with air. An ignition device ignites the mixture of hydrogen and air

so that it burns to power the piston in a conventional manner. The metallic

nozzle is heated via a copper conductor connected to a source of electric

current. The electrical conductors are disposed at the first end of the heat

insulating member. There are totally 9 nozzles in the array. The nozzle is

fabricated of iron alloys and tungsten. The electrical conductors are

manufactured from nickel-copper alloy. The hydrogen gas injector plug is fixed

in an internal combustion engine and a spark plug is mounted on the piston

chamber. Accordingly, it presents a hydrogen gas generator capable of

generating small amounts of hydrogen gas from water available in the atmosphere

BRIEF DESCRIPTION OF THE DRAWINGS

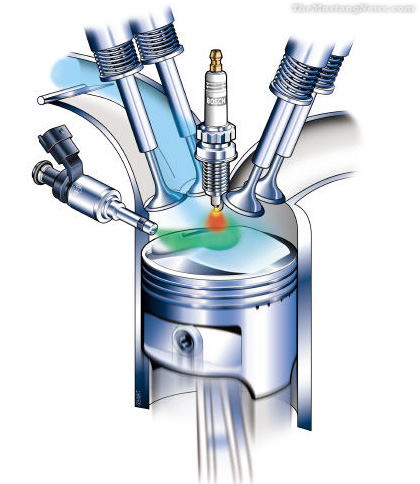

A

piston having rings is housed within chamber. The head and the cylinder wall

are surrounded by coolant chamber. Conventional intake and exhaust valves (not

shown) are also disposed on head. The structure and arrangement of the

aforementioned items are conventional and are not part of this new concept. A

hydrogen gas generator injector plug and a conventional spark plug are mounted

on head. Injector plug and conventional spark plug each have proximate ends

disposed within cylinder chamber.

20- Hydrogen injector plug

22- Circular chamber

22a-

Proximate end of chamber

22b-

Distal end of chamber

24-

Insulation chamber

26- Passageway

28- Cavity

30- Nozzle chamber

34- Electric current conductor

34a- Lower

end of conductor

34b- Upper

end of conductor

36- Four electric conductors

FIG.

2 is a side, sectional view of a hydrogen gas generator injector plug according

to the present invention.

ASSEMBLY OF HYDROGEN INJECTOR PLUG USING

PRO-E

As

in diagram the hydrogen gas generator injection plug comprises a circular

member fabricated from steel and having a threaded proximate end and a distal

end. A passageway extends through member from the distal end to proximate end.

An insulation member is disposed in the passageway. Insulation member is

fabricated from a material having high temperature insulation characteristics.

Member has a first end that is disposed adjacent to, but spaced slightly

inwardly of proximate end. The second end of insulation member extends above

the distal end of member. A passageway extends through insulation member from

second end and terminates at a cavity, which cavity is formed in the first end

of insulation member. A nozzle member is positioned in cavity. Nozzle member is

fabricated from a metal or a metal mixture that has the ability to react with

water at relatively high temperatures to oxidize and generate hydrogen gas.

Nozzle member must also have the ability to become “white hot” very quickly

when an adequate electrical current is applied thereto. As currently

contemplated, iron, certain alloys of iron and tungsten exhibit the requisite

abilities needed to function as the nozzle member. It should be noted however,

that any metal or alloy could be utilized if suitable. An array of hydrogen gas

injector passages is formed in nozzle member. It has been determined that nine

injector passages will provide an adequate amount of hydrogen gas to power

piston. An electric current conductor, preferably fabricated from copper,

extends through passageway. The lower end of conductor abuts nozzle member. The

upper end defines a terminal for an electrical connection. Four electrical

conductors abut the second end of member and are evenly spaced there around.

Conductors are fabricated from a nickel-copper alloy.

WORKING

In

use, ambient air containing water vapor is drawn into the cylinder chamber via

conventional intake valves (not shown) on the intake stroke. A portion of the

air water vapor mixture is forced into injector passages on the compression

stroke. An electric current is applied to nozzle member via conductor during

the latter part of the compression stroke, heating the nozzle member to a

“white-hot” temperature. The water vapor reacts with the metal in nozzle member

to oxidize the metal and produce hydrogen gas. The hydrogen gas expands through

the passages back into the cylinder chamber where it mixes with the oxygen in

the air. Spark plug is fired to

ignite the mixture, which mixture burns thereby creating a high gas pressure to

drive the piston.

Occasionally

(and in some climates), the humidity may be very low and the ambient air will

not contain enough water vapor to produce an adequate amount of hydrogen gas to

properly drive the piston. In such instances additional water vapor is injected

into the intake valve.

ADVANTAGES OF HYDROGEN GAS

Wide Range of

Flammability

Hydrogen has a wide flammability range in

comparison with all other fuels. As a result, hydrogen can be combusted in an

internal combustion engine over a wide range of fuel-air mixtures. A

significant advantage of this is that hydrogen can run on a lean mixture. A

lean mixture is one in which the amount of fuel is less than the theoretical,

stoichiometric or chemically ideal amount needed for combustion with a given

amount of air. This is why it is fairly easy to get an engine to start on

hydrogen.

Generally, fuel economy is greater and the

combustion reaction is more complete when a vehicle is run on a lean mixture.

Additionally, the final combustion temperature is generally lower, reducing the

amount of pollutants, such as nitrogen oxides, emitted in the exhaust. There is

a limit to how lean the engine can be run, as lean operation can significantly

reduce the power output due to a reduction in the volumetric heating value of

the air/fuel mixture.

Low Ignition

Energy

Hydrogen has very low ignition energy. The

amount of energy needed to ignite hydrogen is about one order of magnitude less

than that required for gasoline. This enables hydrogen engines to ignite lean

mixtures and ensures prompt ignition.

Unfortunately, the low ignition energy means that hot gases and

hot spots on the cylinder can serve as sources of ignition, creating problems

of premature ignition and flashback. Preventing this is one of the challenges

associated with running an engine on hydrogen. The wide flammability range of

hydrogen means that almost any mixture can be ignited by a hotspot.

High

Auto-ignition Temperature

Hydrogen has a relatively high autoignition

temperature. This has important implications when a hydrogen-air mixture is

compressed. In fact, the autoignition temperature is an

important factor in determining what compression ratio an engine can use, since

the temperature rise during com\pression is related to the compression ratio.

The temperature rise is shown by the

equation:

Where:

V1/V2 = the compression

ratio

T1 = absolute initial temperature

T2 = absolute final temperature

γ =

ratio of specific heats

The temperature may not exceed hydrogen’s

auto-ignition temperature without causing premature ignition. Thus, the

absolute final temperature limits the compression ratio. The high auto-ignition

temperature of hydrogen allows larger compression ratios to be used in a

hydrogen engine than in a hydrocarbon engine.

This higher compression ratio is important

because it is related to the thermal efficiency of the system .On the other

hand, hydrogen is difficult to ignite in a compression ignition or diesel

configuration, because the temperatures needed for those types of ignition are

relatively high.

High Flame Speed

Hydrogen has high flame speed at

stoichiometric ratios. Under these conditions, the hydrogen flame order of

magnitude higher (faster) than that of gasoline. This means that hydrogen

engines can more closely approach the thermodynamically ideal engine cycle. At

leaner mixtures, however, the flame velocity decreases significantly.

Low Density

Hydrogen has very low density. This results

in two problems when used in an internal combustion engine. Firstly, a very

large volume is necessary to store enough hydrogen to give a vehicle an

adequate driving range. Secondly, the energy density of a hydrogen-air mixture,

and hence the power output, is reduced. speed is nearly an order of magnitude

higher (faster) than that of gasoline. This means that hydrogen engines can

more closely approach the thermodynamically ideal engine cycle. At leaner

mixtures, however, the flame velocity decreases significantly.

AIR/FUEL

RATIO

The theoretical or stoichiometric combustion

of hydrogen and oxygen is given as:

2H2 + O2 =

2H2O

Moles of H2 for complete combustion = 2 moles

Moles of O2 for complete combustion = 1 mole

Because air is used as the oxidizer instead oxygen, the

nitrogen in the air needs to be included in the calculation:

Moles of N2 in air =

Moles of O2 (79%N2in air / 21% O2 in air)

=

1 mole of O2 x (79% N2 in air / 21% O2 in air)

= 3.762 moles N2

Number of moles of air =

Moles of O2 + moles of N2

= 1 + 3.762

= 4.762 moles

of air

Weight of O2 =

1 mole of O2 x 32 g/mole

= 32 g

Weight of N2 =

3.762 moles of N2 x 28 g/mole

=105.33 g

Weight of air =

weight of O2 + weight of N (1)

= 32g + 105.33 g

= 137.33 g

Weight of H2 =

2 moles of H2 x 2 g/mole

= 4 g

Stoichiometric air/fuel (A/F) ratio for hydrogen and air

is:

A/F based on mass =mass

of air/mass of fuel

=

137.33 g / 4 g

= 34.33:1

A/F based on volume =

volume (moles) of air/volume (moles) of fuel

= 4.762 / 2

= 2.4:1

The percent of the combustion chamber occupied by

hydrogen for a stoichiometric mixture:

% H2 = volume

(moles) of H2/total volume (2)

= volume H2/(volume air +

volume of H2)

= 29.6%

These calculations show the stoichiometric or

chemically correct A/F ratio for the complete combustion of hydrogen in air is

about 34:1 by mass. This means that for complete combustion, 34 pounds of air

are required for every pound of hydrogen. This is much higher than the 14.7:1

A/F ratio required for gasoline.

Since hydrogen is a gaseous fuel at ambient conditions it

displaces more of the combustion chamber than a liquid fuel. Consequently less

of the combustion chamber can be occupied by air. At stoichiometric conditions,

hydrogen dis-places about 30% of the combustion chamber, compared to about 1 to

2% for gasoline.

For lean A/F ratios, phi will be a value less than one. For

example, a phi of 0.5 means that there is only enough fuel available in the

mixture to oxidize with half of the air available. Another way of saying this

is that there is twice as much air available for combustion than is

theoretically required.

THERMAL EFFICIENCY

The theoretical thermodynamic efficiency of

an Otto cycle engine is based on the compression ratio of the engine and the

specific-heat ratio of the fuel as shown in the equation:

Where:

V1/V2 = the compression

ratio

γ = ratio of specific heats

ηth = theoretical thermodynamic

efficiency

If the compression ratio and the specific

heat ratio are higher, then the indicated thermodynamic efficiency too would be

higher. The compression ratio limit of an engine is based on the fuel’s

resistance to knock. A lean hydrogen mixture is less susceptible to knock than

conventional gasoline and therefore can tolerate higher compression ratios.

The specific-heat ratio is related to the fuel’s molecular structure.

The less complex the molecular structure, the higher the specific-heat ratio.

Hydrogen (γ = 1.4) has a much simpler molecular structure than gasoline and

therefore its specific-heat ratio is higher than that of conventional gasoline

(γ = 1.1).

EMISSIONS

The combustion of hydrogen with oxygen

produces water as its only product:

2H2 + O2 = 2H2O

The combustion of hydrogen with air however

can also pro-duce oxides of nitrogen (NOx):

H2 + O2 + N2 = H2O + N2 + NOx

The oxides of nitrogen are created due to the

high temperatures generated within the combustion chamber during combustion.

This high temperature causes some of the nitrogen in the air to combine with

the oxygen in the air.

The amount of NOx formed depends on:

•

The air/fuel ratio

•

The engine compression ratio

•

The engine speed

•

The ignition timing

•

Whether thermal dilution is utilized

In addition to oxides of nitrogen, traces of

carbon monoxide and carbon dioxide can be present in the exhaust gas, due to

seeped oil burning in the combustion chamber.

Depending on the condition of the engine

(burning of oil) and the operating strategy used (a rich versus lean air/fuel

ratio), a hydrogen engine can produce from almost zero emissions (as low as a

few ppm) to high NOx and significant carbon monoxide emissions.

POWER OUTPUT

The theoretical maximum power output from a

hydrogen en-gine depends on the air/fuel ratio and fuel injection method used.

As mentioned in Section 3.3, the

stoichiometric air/fuel ratio for hydrogen is 34:1. At this air/fuel ratio,

hydrogen will displace 29% of the combustion chamber leaving only 71% for the

air. As a result, the energy content of this mixture will be less than it would

be if the fuel were gasoline (since gasoline is a liquid, it only occupies a

very small volume of the combustion chamber, and thus allows more air to

enter).

Since both the carbureted and port injection

methods mix the fuel and air prior to it entering the combustion chamber, these

systems limit the maximum theoretical power obtain-able to approximately 85% of

that of gasoline engines. For direct injection systems, which mix the fuel with

the air after the intake valve has closed (and thus the combustion chamber has

100% air), the maximum output of the engine can be approximately 15% higher

than that for gasoline engines.

Therefore, depending on how the fuel is

metered, the maxi-mum output for a hydrogen engine can be either 15% higher or

15% less than that of gasoline if a stoichiometric air/fuel ratio is used.

However, at a stoichiometric air/fuel ratio, the combustion temperature is very

high and as a result it will form a large amount of nitrogen oxides (NOx),

which is a criteria pollutant. Since one of the reasons for using hydrogen is

low exhaust emissions, hydrogen engines are not normally designed to run at a

stoichiometric air/fuel ratio.

Typically hydrogen engines are designed to use about twice as much

air as theoretically required for complete combustion. At this air/fuel ratio,

the formation of NOx is reduced to near zero. Unfortunately, this also reduces

the power out-put to about half that of a similarly sized gasoline engine. To

make up for the power loss, hydrogen engines are usually larger than gasoline

engines, and are equipped with turbochargers or supercharger.

CONCLUSION

Hydrogen

being the lightest element can replace the fossil fuel and acts as a renewable energy

resources .Although the method was developed earlier hydrogen storage was

difficult and dangerous this method injecting hydrogen using the hydrogen gas

injector plug is fruitful overcoming all

the difficulties in storing hydrogen in liquid form and lead to a pollution

free atmosphere . Further the power and fuel consumption is much more better

than the conventional internal combustion engine

REFERENCES

1.Linde Division of Union Carbide

Corporation, "Survey Study of the Efficiency and Economics of Hydrogen

Liquefaction," Contract NAS 1-13395, NASA, Hampton, Virginia, April 8,

1975.

|

Figure 1

|

3.Chao, R.E., and Cox, K.E., "An Analysis of Hydrogen

Production Via Closed-Cycle Schemes," THEME Conference, Miami, Florida,

March 18-20, 1974.

4.www.geocities.com/flynn/hydrofuel/

- A Comprehensive study of hydrogen as fuel

5.Alternate Fuels – Boris

and Davis

No comments:

Post a Comment