RAPID PROTOTYPING

This paper deals

with” RAPID PROTOTYPING” as in

conventional machining process. Rapid prototyping refer to creation of

three-dimensional objects directly from CAD files. And it is the automatic

construction of physical objects using solid freeform fabrication. System of

rapid prototyping to a set of processes in which the physical object is

obtained directly from its cad model without explicitly going through the

various steps of manufacturing which includes tooling and material removal.

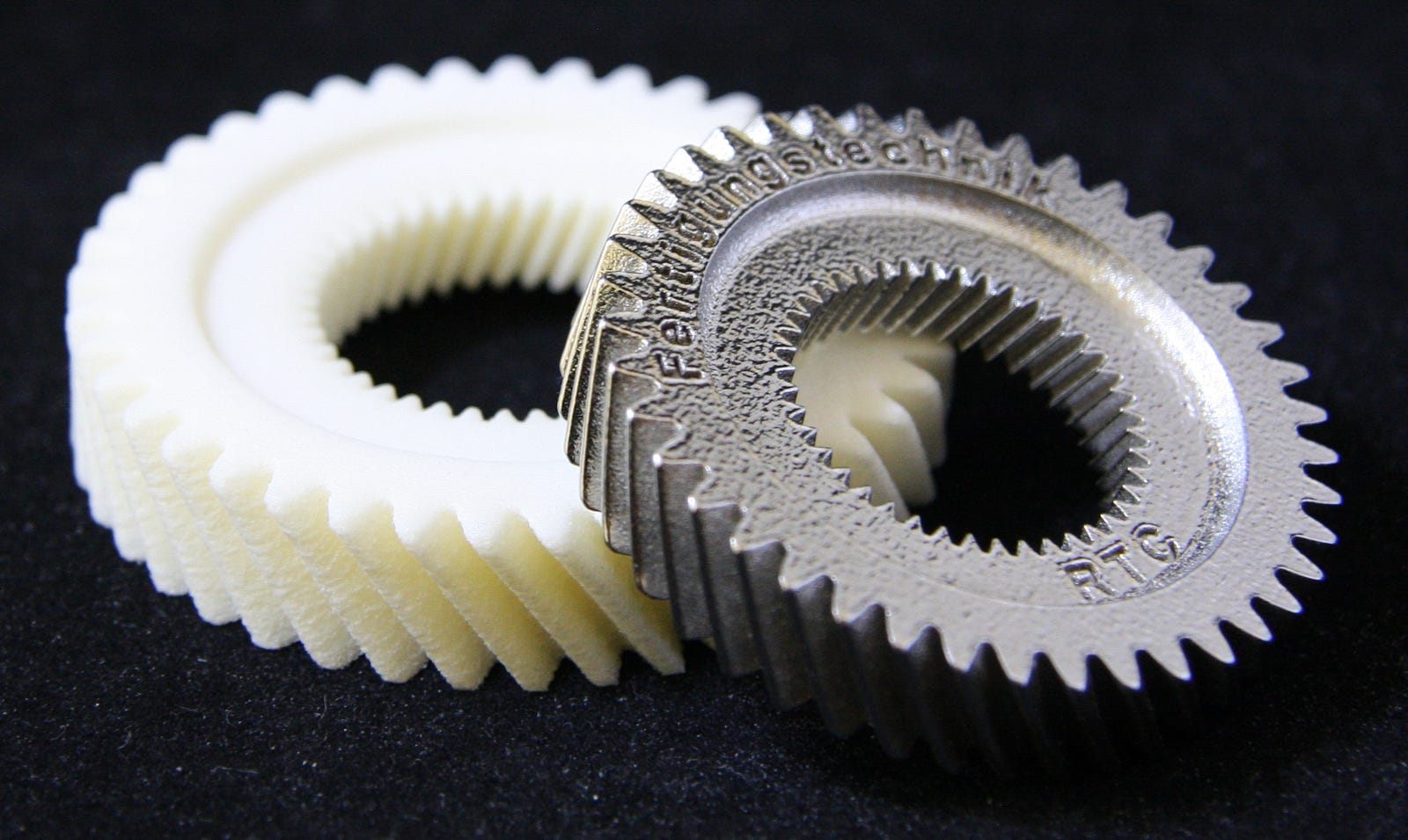

Rapid prototyping system using base materials are thermoplastics, metal

powders, eutectic metals, photopolymer, titanium alloys and various materials.

It advantages is offers direct manufacturing from cad files and sketches and

paperless manufacturing, very past development of functional parts is possible,

it offers greater capability to compute mass properties of components and

assemblies.

INDRODUCTION

Rapid prototyping starts with

quick creation of manufacturing ready, CAD models; continues to verify the

design using CAE (computer aided engineering) tools.the first techniques for

rapid prototyping became available in the late 1980s and were used to produce

models and prototypes parts. Today, they are used for a much wider range of

applications and are even used to manufacture production quality parts in

relatively small numbers. Some sculptors use

the technology to produce complex shapes for fine arts

exihibition.In rapid prototyping,the machine reads in data from a CAD drawing

and lays down successive layers of liquid, powder, or sheet material, and in

this way builds up the model from a series of cross sections.

PROTOTYPING

Prototyping can

resolve uncertainty about how well a design fits the user's needs. It helps

designers to make decisions by obtaining information from users about the

necessary functionality of the system, user help needs, a suitable sequence of

operations, and the look of the interface.

PROTOTYPING METHODS

Various kinds of

prototyping have been developed to obtain different kinds of information such

as requirements animation, rapid, incremental, and evolutionary prototyping.

v Requirements

animation,

in most cases used to demonstrate functionally, is construed in the software

prototype that can be assessed by users.

v Rapid prototyping is a form of collecting

information on requirements and on the adequacy of possible designs.

v Incremental

prototyping

enables large systems to be installed in phases to avoid delays between

specification and delivery.

v Prototyping

evolutionary

considered to be the most involved form of prototyping, is a compromise between

production and prototyping.

RA