Paper on

NITRO SHOCK

ABSORBERS

SYNOPSIS

In the present scenario of

automobile industry manufacturers are trying to produce comfortable and safe

vehicles which the consumers are looking for. A shock absorber is a damping

element of the vehicle suspension, and its performance directly affects the

comfortability, dynamic load of the wheel and dynamic stroke of the suspension.

The conventional type of shock absorbers has got the main drawback that it

causes foaming of the fluid at high speeds of operation. This results in a

decrease of the damping forces and a loss of spring control. The gas filled

shock absorbers are designed to reduce foaming of the oil and provide a smooth

ride for a long period.

INTRODUCTION

For a smooth and comfortable ride

the disturbing forces should be eliminated or reduced considerably by using

some devices. Shock absorbers are such devices which isolate the vibrations by

absorbing some disturbing energy themselves. Of the many types telescopic

shocks are widely used which has got the draw back that the flow of oil in the

cylinder can cause foam of oil and air to form. These limit the optimum

throughout of the flow in the valves. Gas shocks represent an advance over

traditional shocks. Nitrogen filled gas shock absorbers are the results of

years of extensive research and development with top flight shock design

engineers. They are designed for both lowered and stock vehicles to provide

shock absorbers that would out perform anything on the market today. Nitro

shock absorbers are high quality, nitrogen filled shocks designed and gas

charged specifically for each vehicle application. The addition of nitrogen

under pressure limits the foaming effect and increases efficiency.

NEED FOR SHOCK ABSORBERS

Springs alone

cannot provide a satisfactorily smooth ride. Therefore an additional device

called a “shock absorber” is used with each spring. Consider the action of a

coil spring. The spring is under an initial load provided by the weight of the

vehicle. This gives the spring an original amount of compression. When the

wheel passes over a bump, the spring becomes further compressed. After the bump

is passed the spring attempts to return to its original position. However it

over rides its original position and expands too much. This behaviour causes

the vehicle frame to be thrown upward. Having expanded too much, the spring

attempts to compress that it will return to its original position; but in

compressing it again overrides. In doing this the wheel may be raised clear of

the road and the frame consequently drops. The result is an oscillating motion

of the spring that causes the wheel to rebound or bounce up and down several

times, after a bump is encountered. If, in the mean time, another bump is

encountered, a second series of rebounding will be started. On a bumpy road,

and particularly in rounding a curve, the oscillations might be so serious as

to cause the driver to lose control of the vehicle.

A shock absorber is

basically a hydraulic damping mechanism for controlling spring vibrations. It

controls spring movements in both directions: when the spring is compressed and

when it is extended, the amount of resistance needed in each direction is

determined by the type of vehicle, the type of suspension, the location of the

shock absorber in the suspension system and the position in which it is

mounted. Shock absorbers are a critical product that determines an automobile’s

character not only by improving ride quality but also by functioning to control

the attitude and stability of the automobile body.

PRINCIPLE OF OPERATION

The damping

mechanism of a shock absorber is viscous damping. Viscosity is the property of

a fluid by virtue of which it offers resistance to the motion of one layer over

the adjacent on. The main components of a viscous damper are cylinder, piston

and viscous fluid. There is a clearance between the cylinder walls and the

piston. More the clearance more will be the velocity of the piston in the

viscous fluid and it will offer less value of viscous damping coefficient. The

basic system is shown below. The damping force is opposite to the direction of

velocity.

I-CLEARNCE, II-PISTON, III-VISCOUS FLUID

The damping

resistance depends on the pressure difference on the both sides of the piston

in the viscous medium. The figure shown below shows the example of free

vibrations with viscous damping.

The equation of motion for the system can be written as mx + cx +kx

= 0

Energy dissipation in

viscous damping :

For a vibratory body some amount

of energy is dissipated because of damping. This energy dissipation can be per

cycle. Rate of change of work W is called energy. For a viscously damped system

the force F is expressed as

F= cx = cdx/dt, where

x = dx/dt

Work done W = Fx = (cdx/dt) x

The rate of change of work per cycle

i.e. Energy dissipated

Let us assume the simple harmonic motion of the type x = Asinωt

(dx/dt) ² = ω²A²cos²ωt

The

equation for

The

equation for

This shows that the energy dissipation per cycle is proportional to

the square of the amplitude of motion.

The total energy of a vibrating system can be either maximum of its

potential or kinetic energy. The maximum kinetic energy of the system can be

written as E = (KE) max = 1/2mx²max

= 1/2mω²A²

SHOK ABSORBER ACTION

Shock absorbers

develop control or resistance by forcing fluid through restricted passages. A

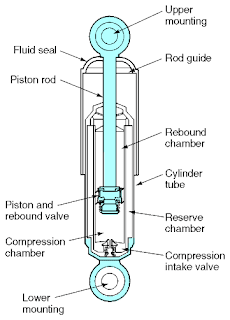

cross-sectional view of a typical shock absorber is shown below. Its main

components and working is also given below.

The inside parts of a shock absorber

The upper mounting is attached to a piston rod. The

piston rod is attached to a piston and rebound valve assembly. A rebound

chamber is located above the piston and a compression chamber below the piston.

These chambers are full of hydraulic fluid. A compression intake valve is

positioned in the bottom of the cylinder and connected hydraulically to a

reserve chamber also full of hydraulic fluid. The lower mounting is attached to

the cylinder tube in which the piston operates.

During

compression, the movement of the shock absorber causes the piston to move

downward with respect to the cylinder tube, transferring fluid from the

compression chamber to the rebound chamber. This is accomplished by fluid

moving through the outer piston hole and unseating the piston intake valve.

During rebound, the pressure in the compression chamber

falls below that of the reserve chamber. As a result, the compression valve

will unseat and allow fluid to flow from the reserve chamber into the

compression chamber. At the same time, fluid in the rebound chamber will be

transferred into the compression chamber through the inner piston holes and the

rebound valve.

|

|

|

Spring

|

Schematic

Diagram of the Interior of a Shock Absorber

|

FORMS OF SUSPENSIONS AND TYPES OF SHOCK ABSORBERS

Various types of

shock absorbers are available in the market. Out of that the widely used types

and their characteristics are given below.

|

Type

|

Product

|

Characteristics

|

|

Double-wishbone

(Multilink) |

Double-tube |

The outer part of the double tube is used as a gas chamber, which is filled with low- pressure nitrogen gas. This type can provide stable damping force. |

|

Single-tube |

Separation between oil and nitrogen gas by a free piston provides stable damping force, as well as high performance. |

|

|

Strut

|

Double-tube |

This type consists of double tubes that comprise part of the support structure of the suspension. Filled with low-pressure nitrogen gas, it provides stable damping force. |

|

Inverted type |

Structurally, this is a single-tube type placed upside down. Its large-diameter pipe provides sufficient rigidity to bear the heavy load from the car body, characteristic of a strut. |

|

|

With a steering arm |

When connected to the power steering system at a point higher than normal, this type allows the cabin space to be expanded and the maneuvering stability improved. |

|

|

Type with separately mounted spring

(rigid axle, etc.) |

Unit damper |

Because the spring is mounted separately, this type features a simple structure comprised of a damping mechanism |

WHY GAS FILLED SHOCK ABSORBERS?

The rapid movement

of the fluid between the chambers during the rebound and compression strokes

can cause foaming of the fluid. Foaming is the mixing of free air and the shock

fluid. When foaming occurs, the shock develops a lag because the piston is

moving through an air pocket that offers up resistance. The foaming results in

a decrease of the damping forces and a loss of spring control.

During the movement of the piston rod, the fluid id

forced through the valuing of the piston. When the piston rod is moving

quickly, the shock absorbers oil cannot get through the valuing fast enough,

which causes pressure increases in front of the piston and pressure decreases

behind the piston. The result is foaming and a loss of shock absorber control.

The need for a gas filled shock absorber arises here.

GAS FILLED SHOCK ABSORBER

The gas filed shock

absorbers is designed to reduce the foaming of the oil. It uses a piston and

oil chamber similar to other shock absorbers. The difference is that instead of

a double tube with a reserve chamber, a dividing piston separates the oil

chamber from the gas chamber. The oil chamber contains a special hydraulic oil

and the gas chamber contains nitrogen at 25 times atmospheric pressure. The schematic

diagram showing the inside parts of a gas filled shock absorber is shown below.

The inside parts of a gas-filled shock absorber.

When the piston rod

is moved into the shock absorber, oil is displaced as in double tube principle.

This oil displacement causes the dividing piston to press in the gas chamber,

thus reducing it in size. With the return of the piston rod the gas pressure

returns the dividing piston to its starting position.

Whenever the oil column is held at a static pressure of

approximately 25 times atmospheric pressure, the pressure decreases behind, the

working piston cannot be high enough for the gas to exit from the oil column.

Consequently, the gas filled shock absorber operates without foaming.

TYPES OF GAS FILLED SHOCK ABSORBERS

- Twin– tube with low pressure gas.

- Single- tube with high pressure gas.

LOW PRESSURE TWIN- TUBE

SHOCKS

Twin- tube gas

technology design retains the classical twin-tube while adding at the top of

the reserve tube nitrogen under relatively low pressure 2.5- 5 bars instead of

25- 30 bars used in high pressure shock absorbers. This pressure is sufficient

to radically improve the efficiency of the shock absorbers.

HIGH PRESSURE SINGLE-

TUBE SHOCKS

Gas shock absorbers

operate in the same principle of movement of the piston in an oil filled tube

but they contain at one end a small quantity of nitrogen under high pressure

(25 bars). The gas is prevented from mixing with the oil by a floating piston.

When the piston rod passes into the body and displaces oil, the oil compresses

the nitrogen even further. The volume of gas changes playing the role as an

equalization tube. The permanent pressure exerted on the oil by the gas

guarantees an instantaneous response and the quieter piston valve operation. At

the same time this constant pressure eliminates cavitations and foaming which

could momentarily degrade the effectiveness of the shock absorber.

WORKING

TWIN– TUBE SHOCK ABSORBERS

:

The main components are:

- Outer tube, also called reservoir

tube

- Inner tube, also called cylinder

- Piston connected to a piston rod

- Bottom valve, also called foot

valve

- Upper and lower attachment

How does it work?

Bump Stroke:

When the piston rod

is pushed in oil flows without resistance from below the piston through the

orifices and the non-return valve to the enlarged volume above the piston.

Simultaneously, a quantity of oil is displaced by the volume of the rod

entering the cylinder. This volume of oil is forced to flow through the bottom

valve into the reservoir tube (filled with air (1 bar) or nitrogen gas (4-8

bar)). The resistance, encountered by the oil passing through the footvalve,

generates the bump damping.

Rebound Stroke:

When the piston rod is pulled

out, the oil above the piston is pressurized and forced to flow through the

piston. The resistance, encountered by the oil on passing through the piston,

generates the rebound damping. Simultaneously, some oil flows back, without

resistance, from the reservoir tube through the footvalve to the lower part of

the cylinder to compensate for the volume of the piston rod emerging from the

cylinder.

MONO- TUBE SHOCK ABSORBERS

:

The main components are:

- Pressure cylinder, also called

housing

- Piston rod connected to a piston

rod

- Floating piston, also called

separating piston

- Piston rod guide

- Upper and lower attachment

How does it work?

Bump Stroke:

Unlike the bi-tube damper,

the mono-tube has no reservoir tube. Still, a possibility is needed to store

the oil that is displaced by the rod when entering the cylinder. This is

achieved by making the oil capacity of the cylinder adaptable. Therefore the

cylinder is not completely filled with oil; the lower part contains (nitrogen)

gas under 20-30 bar. Gas and oil are separated by the floating piston. When the

piston rod is pushed in, the floating piston is also forced down the

displacement of the piston rod, thus slightly increasing pressure in both gas

and oil section. Also, the oil below the piston is forced to flow through the

piston. The resistance encountered in this manner generates the bump damping.

Rebound Stroke:

When the piston rod is pulled

out, the oil between piston and guide is forced to flow through the piston. The

resistance encountered in this manner generates the rebound damping. At the

same time, part of the piston rod will emerge from the cylinder and the free

(floating) piston will move upwards.

ADVANTAGES OF NITRO SHOCKS

Instantaneous response :

- Because the high pressure

eliminates aeration (foaming), action is always is immediate.

- The low mass of gas and the single

tube further improves response time.

Better fade resistance :

- Since there is no outer tube,

cooling is much better which gives a drastic reduction in fade. Thus more

consistent handling and control.

Better durability :

- Single-tube construction also allows

for a larger internal working area, reducing stress and fatigue for better

durability.

- De Carbon’s monodisc valving

system features a single moving part that drastically reduces inertia and

friction, to improve durability and performance.

- Better cooling of the mono tube

design results in lower operating temperatures and thus longer life.

No need for re-adjustment:

- The viscosity of hydraulic fluid

changes as temperature changes. This may because of climate, season

(summer/winter) or heavy duty (motorway cruising). The high pressure gas

compensates immediately and automatically for changes in viscosity.

TIPS

BEFORE MOUNTING

A stiff suspension

does not necessarily mean good handling. Often the contrary. If still a stiff

suspension is needed it should come from the springs. The

function of the shock absorber is to dampen oscillations of the spring by

converting energy to heat. Do not use shock absorbers to obtain a stiff

suspension. Shock absorbers and springs each have their own function. Respect

those functions.

Do

not use new shocks to compensate for old and tired springs. The shocks will

soon fail when the springs are bad. Worn shocks do not only reduce safety and

handling, they also increase the risk of having a broken spring as the spring

is allowed to oscillate.

When

to buy shocks?

Shock absorbers last a long time, but they

tend to degrade slowly throughout their life. So when is it time to replace

them?

In

some cases, a seal will rupture. A shock covered in oil is a good indication

that it has failed. The age-old test of bouncing on a fender is really only a

rough guide as to whether the vehicle needs new shocks. Usually the slow

degradation in shock absorber's performance won't be noticed until it affects

handling fairly dramatically. Depending on how rough the roads are, modern

shocks can last 80-100,000 miles, but remember that a shock with 60,000 miles

on it won't perform as well as a new one.

Which

ones are right?

Choosing which shocks to buy largely depends upon what

kind of vehicle and the kind of driving. As with most automotive components, it

is important the specific vehicle, since mismatched shocks can drastically

affect handling and could even be dangerous. The best advice will probably come

from a mechanic who is familiar with the vehicle.

CONCLUSION

In the current scenario of automobile industry the need for vehicles

which provides smooth and comfort ride is growing. Nitro shock absorbers are

designed to be ultimate in performance and comfort. In a country like ours

whose roads are not up to world standards the need for automotive components

like nitro shocks are necessary. It goes without saying that if the right

choice is made the improvements in vehicles ride and handling can be shocking.